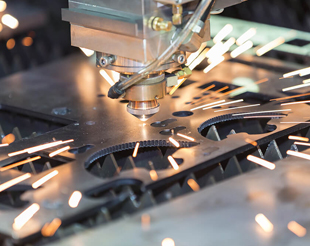

Laser Cutting

laser cutters create patterns and designs by cutting into materials. A powerful laser beam is the source that melts, burns, or vaporizes the material.

Essentially, laser cutting is a fabrication process that uses a thin, focused, laser beam to cut and etch materials into custom designs, patterns, and shapes as specified by a designer. This non-contact, thermal-based fabrication process is ideal for several materials, including wood, glass, paper, metal, plastic, and gemstone. It’s also capable of producing intricate parts without needing a custom-designed tool.

A laser cutter’s beam usually has a diameter between 0.1 and 0.3 mm and a power of between 1 to 3 kW. This power needs to be adjusted depending on the material being cut and the thickness. To cut reflective materials like aluminum, for instance, you may need laser powers of up to 6 kW

Laser cutting is not ideal for metals like aluminum and copper alloys because they have excellent heat-conductive and light-reflective properties, meaning they need powerful lasers.

Laser metal cutting offers many benefits, and some of them are the following:

- low heat input on metal

- small deformation of the metal

- high speed

- high quality cut

- flexibility

- cost-effectiveness

- precision